Banjo fittings play a vital role in hydraulic, automotive, and industrial systems. You rely on them when space is tight and pressure is high. Their compact and flexible design ensures a secure connection where reliability matters most.

What is Banjo Fitting?

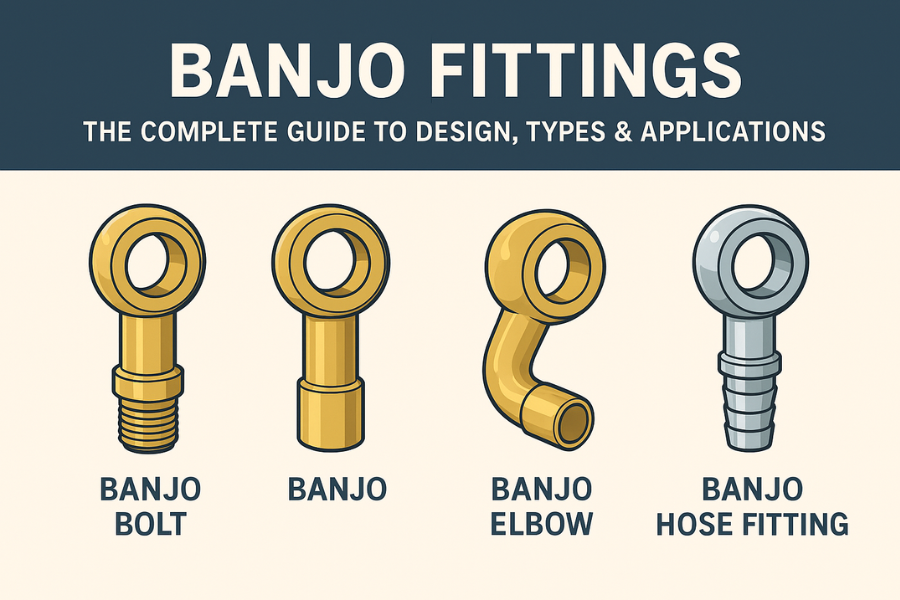

A banjo fitting consists of two parts:

- Banjo bolt: A hollow bolt with axial and radial holes.

- Banjo body (eye fitting): A ring-shaped connector that the bolt passes through.

The design allows fluid to flow through the bolt and into the hose or pipe. The name comes from its resemblance to the round body of a banjo instrument.

How Do Banjo Fittings Work?

The process is simple yet effective:

- Assembly: The bolt passes through the fitting body.

- Sealing: Washers or O-rings compress between the fitting and the surface.

- Flow: Fluid enters through the hollow bolt and exits into the hose.

- Alignment: The fitting body rotates around the bolt for flexible hose routing.

You gain a leak-proof, vibration-resistant connection that suits confined spaces.

What Materials and Threads Are Available?

Banjo fittings come in different materials to match performance needs:

| Material | Key Benefit | Typical Use |

| Stainless Steel | High strength, corrosion resistance | Brake lines, hydraulics |

| Brass | Corrosion resistance, easy machining | Fuel systems |

| Aluminum | Lightweight, corrosion resistance | Racing, performance vehicles |

Thread standards vary by region:

- Metric (M10, M12, M14) dominate automotive and motorcycle systems.

- BSPP threads appear in European and Asian hydraulics.

- NPT threads are common in North American hydraulics.

Industry data shows that over 60% of automotive brake systems use metric banjo fittings due to global standardization.

What Types of Banjo Fittings Exist?

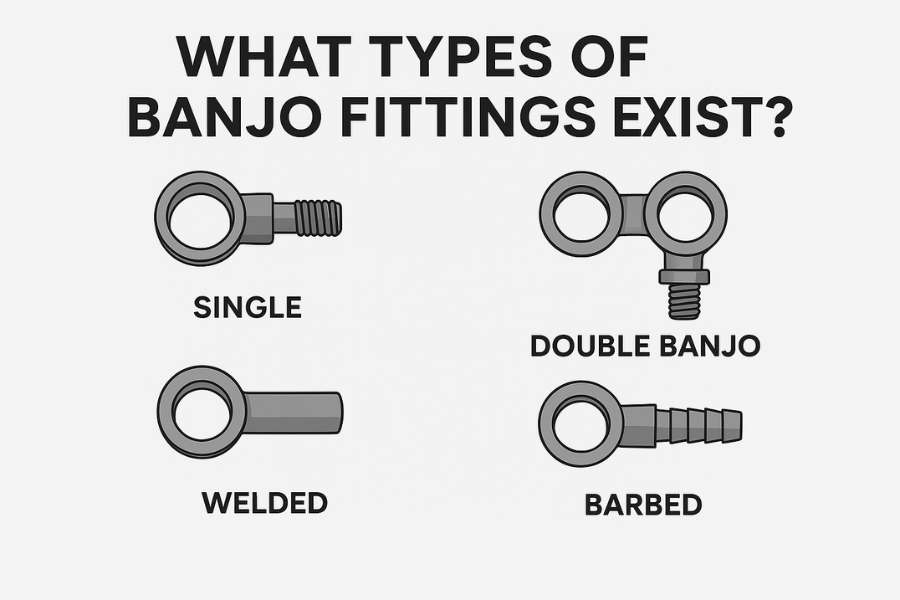

You can choose from several designs:

- Single banjo fitting – One fluid line connection.

- Double banjo fitting – Two lines from one bolt, saving space.

- Welded banjo fitting – Handles pressures up to 9,000 PSI.

- Barbed banjo fitting – Secures soft hoses with barbs.

Each type serves a unique role. For example, double banjo fittings reduce space requirements in motorcycle brake systems.

How Does Zero-Leak Gold Improve Performance?

Traditional banjo fittings use crush washers. They often require high torque, risk thread damage, and create multiple leak paths.

Zero-Leak Gold (ZLG) fittings solve these problems. They feature:

- Dual metal-to-metal seals based on SAE J1926 and ISO 6149.

- O-ring back-up seals for redundancy.

- Low torque installation.

- Resistance to vibration, pressure spikes, and temperature changes.

Independent testing shows ZLG fittings reduce leak risk by over 90% compared to crush washer designs.

Where Are Banjo Fittings Used?

Banjo fittings appear in multiple industries:

- Automotive and motorcycles: Brake systems, fuel lines, turbo oil feeds, power steering.

- Hydraulic machinery: Excavators, power packs, mobile hydraulics.

- Industrial equipment: Steel plants, paper mills, robotics.

- Specialized systems: Agricultural machinery, diesel engines, air conditioning.

Global market reports indicate that hydraulic applications account for nearly 45% of banjo fitting demand.

What Sizes and Variants Are Available?

Banjo bolts come in a wide range:

- Metric sizes: M8, M10, M12, M14, M16.

- Custom lengths: Designed for single or double fittings.

- Surface finishes: Zinc-plated, stainless, or anodized for corrosion resistance.

You can match the bolt to your system’s pressure and durability requirements.

FAQs

Q1: Why are they called banjo fittings?

The round body resembles a banjo instrument.

Q2: What are banjo bolts used for?

They secure the fitting to a component while allowing fluid to pass through.

Q3: Do banjo fittings leak?

Washer-based designs may leak after reuse. ZLG fittings eliminate most leak paths.

Q4: Can banjo fittings handle high pressure?

Yes. Welded fittings withstand pressures up to 9,000 PSI.

Q5: What industries use banjo fittings?

Automotive, aerospace, hydraulics, and industrial machinery.

Key Takeaways

- Banjo fittings deliver compact, flexible, high-pressure connections.

- Stainless steel, brass, and aluminum options cover diverse needs.

- Single, double, welded, and barbed types serve different systems.

- Zero-Leak Gold technology ensures superior sealing and durability.

- Automotive, hydraulic, and industrial markets rely heavily on banjo fittings.

“Home Dwellish — Bringing you fresh ideas for better living spaces.”